Copper Alloy Machining Services

Guangdong JS Alloy Material Co. Ltd takes great pride in being a renowned manufacturer of a diverse range of copper materials. One of our key specialties lies in being the leading producer of Beryllium Copper Alloy in China.

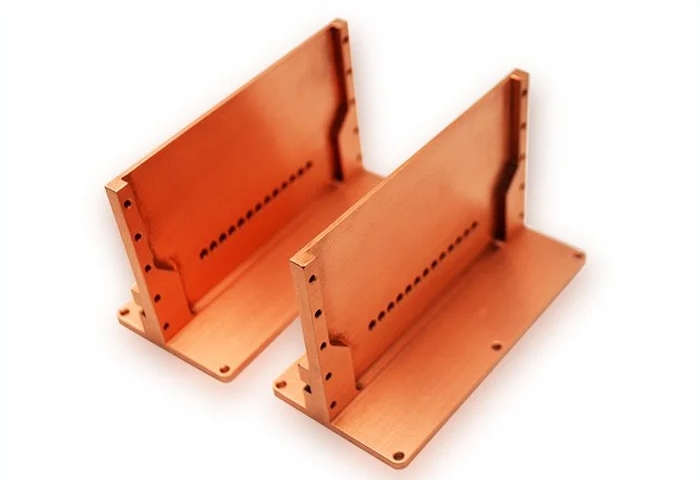

In addition to our Beryllium Copper Alloy, we are delighted to offer a comprehensive range of precision machined or milled parts made from brass, bronze, and copper alloys. These parts are meticulously crafted to your exact specifications, ensuring a perfect fit. Our team is committed to producing high-quality custom precision bearings, bushings, flanges, washers, double flange bearings, full half bearings, spacers, and other special machined parts. These components can be shipped worldwide, adhering to the highest international standards.

We proudly serve various industries, including oil and gas, aerospace, mining and construction, agricultural, transportation and railways, telecom, automotive, medical, and fluid controls. Our machined parts are designed to meet the stringent requirements and demanding applications of each industry.

At JS Alloy Material, we continually invest in our state-of-the-art manufacturing facilities, production equipment, and testing equipment. Our arsenal includes a range of advanced CNC machines, ensuring precise and efficient production processes. Moreover, our exceptional management and skilled operators work harmoniously as a unified team, dedicated to delivering top-notch quality machined parts.

We are committed to providing you with the finest products and outstanding service, meeting your specific copper material needs and exceeding your expectations.

Common Uses Of Beryllium Copper Alloys

1.Utilizing Beryllium Copper Alloys for Conductive Elastic Elements and Sensitive Components

Over 60% of the beryllium copper produced is utilized as an elastic material, finding extensive applications in the electronics and instrument industries. It serves as a crucial component in various elastic elements, including switches, reeds, contacts, bellows, and diaphragms. These components play a vital role in ensuring optimal performance and reliability in electronic devices and instruments. Their flexibility and resilience make beryllium copper an ideal choice for these applications.

2.Harnessing the Power of Beryllium Copper Alloys in Sliding Bearings and Wear-Resistant Components

Thanks to its exceptional wear resistance, beryllium copper alloy has become a preferred choice for manufacturing bearings in computers and civil airliners. A notable example is American Airlines, which successfully replaced copper bearings with beryllium copper bearings, resulting in a significant increase in service life from 8,000 hours to an impressive 28,000 hours.

Moreover, beryllium copper finds extensive use in the production of wires for electric locomotives and trams. These wires offer a multitude of advantages, including corrosion resistance, superior wear resistance, high strength, and excellent conductivity.

3.Beryllium Copper Alloys: The Go-To Choice for Explosion-Proof Tools

In industries such as petroleum and chemicals, beryllium copper is highly valued for its non-sparking properties. This unique characteristic allows for the production of various operating tools using beryllium copper. These tools prove to be invaluable in environments where the risk of sparks can lead to hazardous situations.

Furthermore, the use of beryllium copper operating tools extends to a wide range of explosion-proof works. The exceptional properties of beryllium copper, combined with its ability to prevent sparks, make it a reliable choice for ensuring safety in potentially explosive environments.

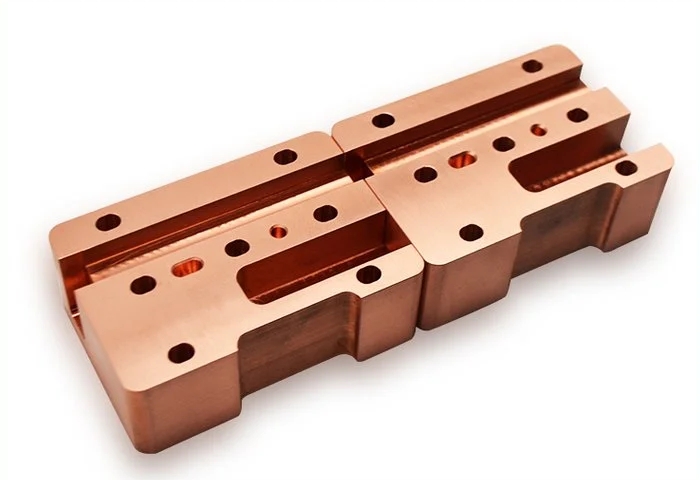

4.Unleashing the Potential: Beryllium Copper Alloy Applications in Molds

The exceptional properties of beryllium copper alloy, including its high hardness, strength, excellent thermal conductivity, and impressive castability, make it an ideal choice for direct casting of molds with extreme precision and complex shapes.

Furthermore, molds made of beryllium copper alloy exhibit superior finish, clear patterns, and shorter production cycles. Additionally, the old mold material can be reused, resulting in cost savings. Beryllium copper alloy is widely employed in various applications, including plastic molds, pressure casting molds, and precision casting molds. Its versatility and reliability make it a preferred material in the mold-making industry.

5.Powering Efficiency: The Versatile Applications of Beryllium Copper Alloys in High-Conductivity Industries

Take, for instance, the Cu-Ni-Be and Co-Cu-Be alloys, which boast remarkable strength and electrical conductivity, reaching conductivity levels of up to 50% IACS. These highly conductive beryllium copper alloys find significant application as contact electrodes in electric welding machines and as elastic components with superior conductivity in electronic products. As the demand for high-conductivity materials continues to grow, the application range of these alloys is steadily expanding, catering to various industries and products requiring exceptional electrical performance.